“I break my skis because I ski too hard” is something of a humblebrag, but frankly it’s getting expensive and annoying! There are many ways that you can break skis, as I have documented in my ski equipment I have killed page, that are not specifically to do with skiing technique – delaminating tails for example is often caused by banging them on the ground to dislodge snow before you stick them in your car. What I’m talking about here though is definitely a consequence of how I ski. So let’s talk about cornering.

Modern “parabolic” skis have a sidecut, where the tip and tail are wider than the middle, and there’s a curve between them down the length of each side of the ski. If you tilt a ski to one side, it will rest on the edges at the tip and tail, and the middle will be lifted off the ground. If you then apply force to the middle of the ski (by standing on it), the ski will bend until the middle of the ski touches the ground. The ski will then be bent along its length, and where the edge meets the ground it will form a curve, which is roughly a segment of a circle, and when the edge runs along the ground along this curve, the ski will turn. The more sidecut, the more force, the more flex of the ski, the shorter the radius of the circle, and consequently the tighter the turn you can do. This happens particularly when you do a kind of skiing known as carving introduced in the early 1990s, which is in contrast to the technique that preceded it known as parallel, which is more or less skidding. A key difference between the two is that when carving a turn, the ski doesn’t move sideways (much) relative to the ground. This makes carving smooth, quiet, stable, and also preserves speed through the turns, but it puts a lot more force on the edges – I’ve measured myself (75kg + kit) pulling 3.5g in corners, and that makes for a lot of pressure on those edges. Skidding is still useful, especially for losing speed, stopping, performing very abrupt manoeuvres, or in confined spaces like couloirs or lift queues.

Here’s a pic of me carving on the exact skis I talk about below:

A ski is typically constructed from a sandwich of layers of different materials chosen for strength, stiffness, vibration absorbing, water resistance, and so on. It might look something like this in cross-section:

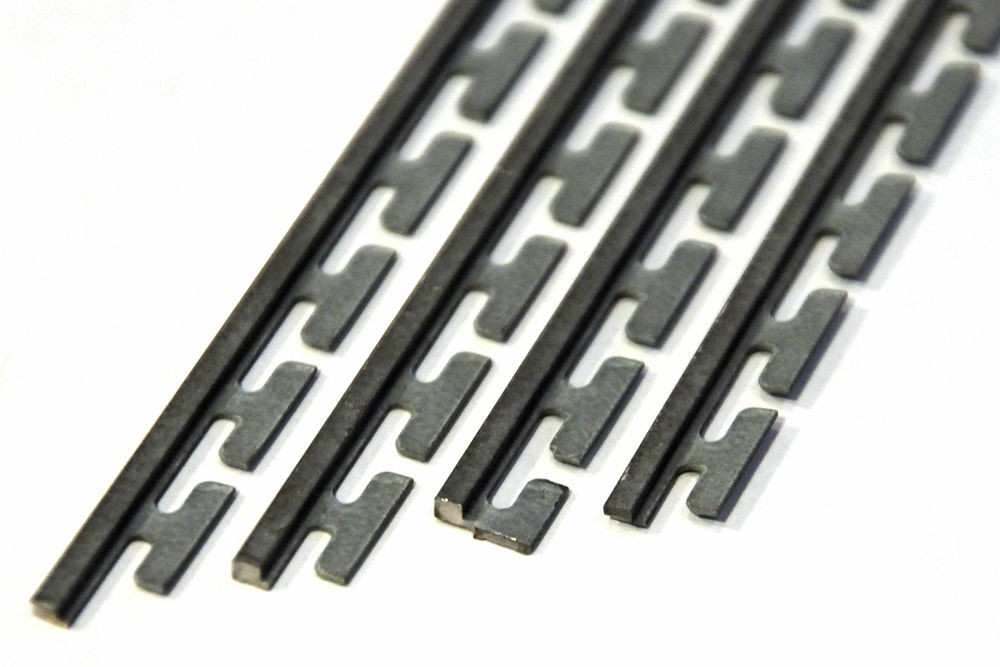

This is only a rough idea, and the structure varies widely, but however the ski is constructed, the edges (which provide grip on hard, icy surfaces) are usually the same: a square steel section with a flange that extends into the body of the ski – the little red bits in the diagram above. Steel is strong, hard, but not very flexible, so edges are thin, around 2-3mm square in section, with the flange extending perhaps 10mm into the ski. The flange is segmented so that it remains well-anchored within the ski structure without adversely affecting the flex of the ski. These are bare edges, before being built into skis:

When the ski turns, it’s put on its edge and force applied. This results in a strong torsional force on the edge:

I had a few goes at using AI chats to figure out exactly how much torque is applied, and it’s quite tricky, however, for a 75kg skier (me) exerting 3g of lateral acceleration (that’s pretty hard!), it apparently works out at around 5Nm of steady-state torque, which is about what you can do by hand with a screwdriver. It doesn’t sound much, but that edge is really quite small, that’s a fair amount of torque, and in reality, it will be changing very rapidly, with peaks well above that value. All that force, applied repeatedly over many ski days, leads to this:

Here the torque acting on the edge has caused it to rotate out of the structure of the ski, partly levering the base away from the ski core. Here’s what it looks like on a real ski (my beloved Elan Wingman 82 prototypes, just 2 years old):

You can just make out the segmented flanges inside the crack. If you look across the width of the ski, you can see that the base is raised on one side, and the base material sits proud of the steel edge, when it should be flush. The time you’re most likely to spot this is when waxing your skis, and before you see cracks forming, you might see the base developing bulges or ridges, usually just ahead of the bindings on the inside edges, where the most stress occurs during turns.

This condition is somewhat dangerous because the edge is no longer firmly attached to the structure of the ski, and a gap between edge and base can open up, making it more likely to catch on a rock and completely tear the edge out of the ski; not good if you’re going fast at the time. Water can also get into the crack and damage the ski core, by frost cracking, mould, rust, etc.

This is quite different to the kind of damage that can occur when you hit a rock, as I did on my Salomon Q105s a couple of years ago:

This cracked the edge, and impacted the ski body, but only over a very short length, and there was no base bulging, but this was also fatal damage and the skis were unsafe to ski on.

So what’s the problem? Skiing is a very dynamic activity that’s tough on equipment, so shouldn’t we expect skis to wear out? Not so much. Skis will break in extreme circumstances like hitting rocks, but when using them exactly as intended, I don’t expect them to simply lose structural integrity, and they should last for many years. Also I wouldn’t mind so much if this was a one-off, but this is the 5th pair of skis that I’ve done this to, and it’s getting expensive! These are the skis I’ve done this to so far – multiple manufacturers across several years, so it’s not like I’m suffering from a bad batch!

- Rossignol Scratch BC

- Volkl AC50 Unlimited

- Fischer RC4 slalom skis

- Dynastar Cham 97 freeride skis

- Elan Wingman 82 prototypes

So please, dear ski manufacturers, make your skis stronger! If you ask me nicely, I’ll help you test them (maybe to destruction)!